How to make the 3 preparatory refreshments for stiff sourdough

I know you’ve been waiting a long time for this second post, How to make the 3 preparatory refreshments for stiff sourdough, after the first one I left you on How to make a stiff SD for Panettone. I wanted to wait for this time of year when many of you are used to preparing your stiff sourdough for Christmas. Or at least you have it in mind. It’s the intention that is important, hahaha.

Well, today I will tell you how to proceed in the first step of making your panettones. I will show you how to make the 3 preparatory refreshments, but also know some things that intervene in this step and that, no doubt, we must take into account. Without forgetting some possible problems that may arise during the process and how to solve them.

Starting on this fascinating journey.

If we want to make a Panettone with sourdough (SD), the first thing we have to do is to make this natural ferment and educate it for a while. It’s a long process, I know, but I can also promise you it’s worth it. And if you take care of it, you won’t have to do it once in your life.

In case you don’t have your stiff SD yet, I remind you of this post where I detail and explain the whole process, as well as being accompanied by a video where you can see the process. But, if you still want to see much more, last year I shared daily in my stories (highlights) all this process from scratch. And, once the process is over, I share my experience and opinion. If you are interested, you can see it in my Instagram profile in the highlighted stories.

Once we have our stiff sourdough…

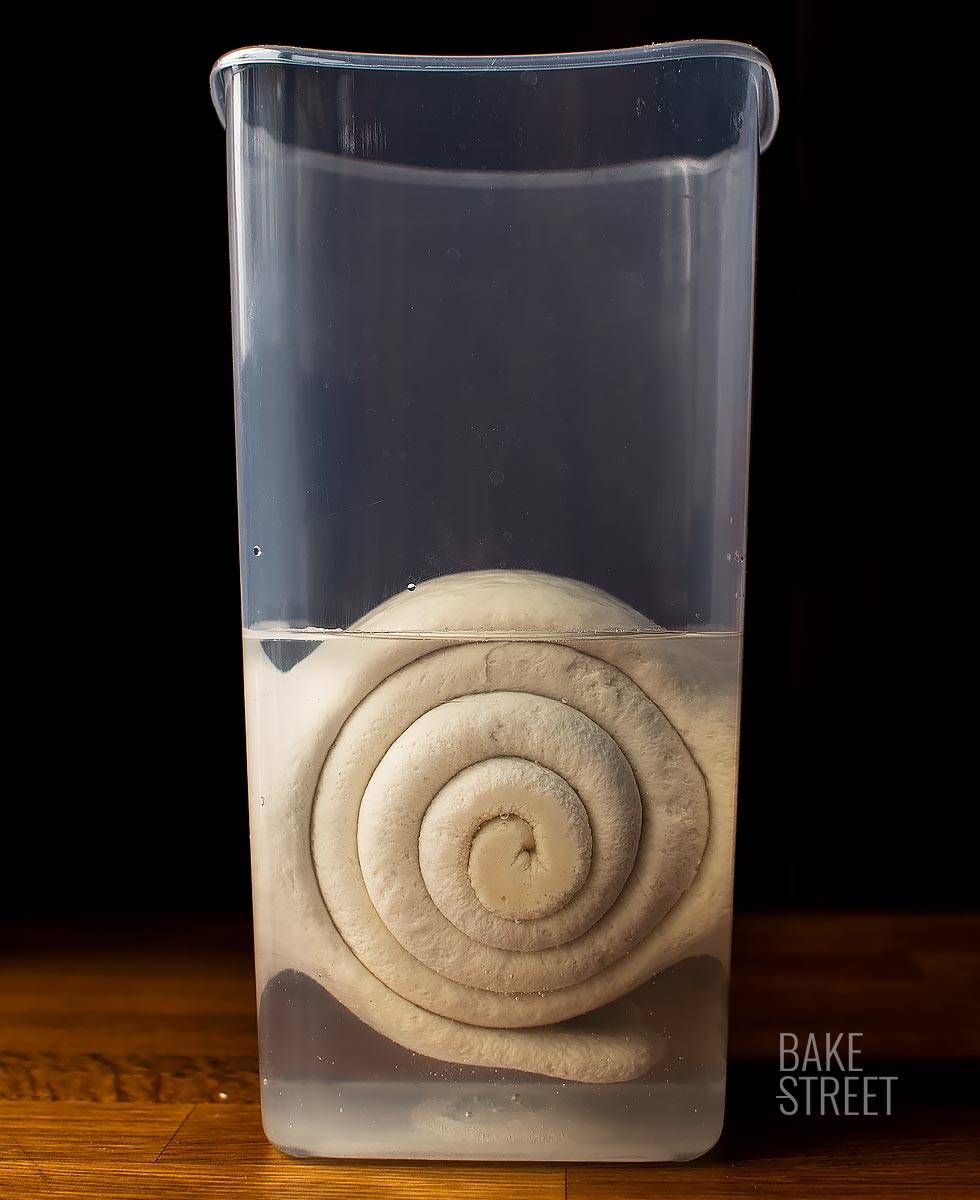

If you followed my process of elaboration, or that of another person who works in the same line, you will have elaborated a stiff SD immersed in water. But it may be that you have started it by another process and you have made it dry. In both cases we will obtain magnificent results, only that it is necessary to work with them of different way since they behave of different way.

Our first step will be to make a bagnetto to the sourdough.

What is bagnetto?

It is a question of submerging the stiff SD, previously drained in our case, in a specific proportion. The quantity of water in relation to the quantity of SD would be 3:1, that is, we use 600 g of water for each 200 g of SD and 0.5 g of sugar per liter of water. Time should always be around 15-18 minutes.

Although some people consider that this process must be carried out every day, we must first take into account what effect the bagnetto has on the sourdough.

By submerging the SD in a sweetened bath, what we achieve is to reduce its acidity, but we also weaken it. Therefore, if every day we let our stiff SD acidify, in this case it would be good to give it a daily bath. But, if we control well the process of night rest avoiding excessive acidification, it will be enough to do it once a week or before proceeding to make a panettone (this is the way I do it). This process is more suitable for dry stiff SD method.

How to proceed…

- Dry/sac sourdough method: In this case we must make the bagnetto, without being able to avoid this step. The sugar gives oxygen to the water and allows it to be supplied little by little. The time of the bagnetto should be around 15/18 minutes to allow the acidity and other substances responsible for the acidity to settle and deposit.

- Submerged sourdough method: In this case the sourdough produces more lactic acid and the result will be a less acidic sourdough, as part of that acidity is diluted in the water. In this case, with bagnetto, we will not need to lower its acidity, but it would be necessary, above all, if we have used refrigerators for the night rest of the SD. Remember that yeasts, when subjected to low temperatures, fall asleep. In this case the temperature of the bath water should be around 91,4º/95ºF – 33º/35ºC. In this case, due to the temperature of the hot water, it is a process that could be repeated daily if we wish.

The refreshment processes of a SDs should be done when the SD is fully mature. In the hypothetical case that we decide to use a SD that has passed this point of maturity, we must know that its state will be acid. To reduce this acidity, we should proceed to make a cold water bath with the proportions (water, sugar) specified above.

Why doesn’t my SD float during the bagnetto?

It can happen that during the first step of the process we find a SDs that does not float. This is because there is too much activity on the part of the microorganisms and has caused our SDs to become very acidic and have a very low pH.

To solve this problem, we will apply the solution that I specify you below -> Quality of our sourdough -> Lievito very strong.

Before being used to make a Panettone, it must be fortified by refreshing it 3 times before being used in the first dough or Primo Impasto.

IMPORTANT NOTES TO KEEP IN MIND WHEN PREPARING OUR STIFF SD

When we carry out a fermentation process in a dough, it is necessary and important to take into account what is the right temperature to carry out a correct and optimal metabolic process. This is given to the great variety of microorganisms present in a dough.

Yeasts have an optimal range that can vary between 78,8º – 86ºF/26º-30ºC. To favour a correct reproduction of these yeasts, the final temperature must be between 78,8- 82,4ºF/26º-28ºC.

This value is very important not only for an optimal reproduction and environment for yeasts, but also for the correct formation of the gluten mesh.

A cold dough, with a temperature below 71,6ºF/22ºC, will have a gluten partially formed and with a slower fermentation process. On the other hand, a warm dough with a temperature above 86ºF/30ºC will have a high enzymatic activity and will tend to liquefy.

- Yeasts in an environment of 32º-39,2ºF /0º-4ºC, will have zero fermentative activity.

- Yeasts in an environment of 39,2º – 53,6ºF/4ºC-12ºC, experience a deceleration of the fermentative activity.

- Atmosphere around 53,6º- 68ºF/12º-20ºC, the fermentative activity linked to heterofermentative lactic bacteria is resumed and the fermentative resistance of the yeasts is improved.

- Environment around 68º- 82,4ºF/20º-28ºC, exponential growth of yeasts with a high production of gases.

- Temperature around 82,4º- 95ºF/28º-35ºC, maximum gas production is produced and progressive yeast deterioration begins.

Fermented products with SD, compared to those fermented with yeast, behave differently, as do the end results which are definitely much better. In general the products obtained are much more digestive and have a better shelf life, since they are preserved for much longer.

We must also bear in mind that they have a different rhythm when it comes to fermenting dough, it behaves differently depending on the temperature and consistency of the dough and the acidity has a direct effect on the dough.

How do we know when our SD is at its optimal point to be used?

Before proceeding to make the bagnetto and the 3 preparatory refreshments, we must start from a strong, stable and predictable stiff SD. That is to say, we must have been feeding it daily according to its needs to start it up before subjecting it to the fermentation of a dough like Panettone.

The SD that we will prepare to make a bagnetto as a next step, must have been refreshed in a range of 12-14 hours before reaching the correct maturity in an environment with a temperature around 75,2º-78,8ºF/24º-26º.

The final value of a mass is determined by 4 factors:

- Ambient temperature

- Flour temperature

- Water temperature

- Heat provided by the type of mixer

If you look at two of them, we can only intervene to determine the final result of the temperature. This is what is called base temperature and must be calculated whenever we are going to work with a dough. Always.

A hard, dry dough will heat up more during the kneading process due to the friction that will produce more heat. A dough with a smoother consistency will heat less.

How is the base temperature calculated?

There is a formula that helps control the final temperature of a dough:

Base temperature = Flour temperature + Water temperature + Ambient temperature

From where we can calculate any of them, as for example in this case that it is the one that interests us, the temperature of the water:

Water temperature = Base temperature – (Flour temperature + Ambient temperature)

With this data we can calculate the final result because we know all the elements involved:

- Kneader, its friction can vary: arm kneader (42,8º-48,2ºF/6º- 9ºC), spiral kneader (50º-59ºF/10º-15ºC) and planetary kneader (59º-66,2ºF/15º-19ºC). The kneading or kneading medium would correspond to the base temperature.

- We can control the temperature of the flour by chilling it

- The ambient temperature can be controlled in some spaces, in which it is not, we must know which is the one that has exactly

- We can control the temperature of the water to achieve the final base temperature we are interested in. Either using cold water from the fridge, with ice or even warm. When the water varies by 37,4ºF/3ºC, either upwards or downwards, the temperature of the final mass varies by 33,8ºF/1ºC in the same direction.

Another way to calculate the water temperature is:

For example: Taking into account the type of mixer -> Spiral mixer = 53,6ºF/12°C (friction temperature of that particular mixer)

- Desired mixing end temperature -> 77ºF/25°C

- 25 x 3 (the latter is the number of factors we are going to value: flour, ambient t., friction) = 75

- Flour temperature -> 77ºF/25°C

- Ambient temperature -> 82,4ºF/28°C

- Kneader temperature (spiral) -> 53,6ºF/12°C

- 25 + 28 + 12 = 65

So 75* – 65 = 50ºF/10°C (is the temperature at which the water must be to obtain 77ºF/25°C of final kneading)

* Number obtained by multiplying the desired temperature by the number of influencing factors.

Quality of our stiff SD.

Once we have a stable stiff SD with a period of “maturation and learning” by this, we can assess its quality based on some data.

Lievito mature: it will have a good smell, with a sweet and slightly acid taste in the mouth, the colour will be warm white, with elongated alveoli and an optimum pH of 4,1-4,3.

Lievito very strong: A very strong SD can occur in two situations; strong and not acid or strong and acid. A strong, non-acidic SD is a SD that has produced many yeasts breaking the balance with lactic acid bacteria, but not in excess.

If this is the case, the SD must be carefully observed because it may be ready earlier than planned. Even without unpleasant or strong odours. If a SD is ready within 3 hours, something is wrong.

It may also be that it is too strong because it produces acetic acid, in which case we would perceive a bitter taste, a greyish colour, round alveoli, a PH<4, a spicy-acid aroma and a sticky consistency. In this case, the SD must be purged to slow down yeast production.

- Make a bagnetto with cold water at 64,4ºF/18ºC adding 2 g of sugar per litre of water. Remember that we will add 300 g of water per 100 g of SD. Leave in the bath for 15-20 minutes. After this time, drain the SD and refresh following these steps.

- Mix 200 g SD with 400 g flour W=360-380 and 210 g water. The percentage of water is 35%, this is due to the amount of water that can be absorbed in the bagnetto. And proceed as usual. The quantities are an example, based on the proportion, adjust the quantities with which you feel comfortable at home.

Lievito very weak: In this case we will find a very sweet SD, without peaks of acidity, very white color and practically absent of alveoli. The pH will be 5-5.5 and the smell of flour. To reinforce it, proceed as follows:

- Sourdough 250 g (100%), 200 g flour (80%) and 90 g water (45%). Let the SD grow in an environment at 82,4ºF/28ºC. Continue with the following refreshments, gradually returning to the quantities of water and flour with which we initially worked, until you obtain a SD with a desired consistency and that grows its initial volume once and a half in a period of 3 or 3 and 1/2 hours.

Lievito sour: In this case we find a SD with a spicy smell, strong, can even remember the cheese due to an excess of butyric acid, bitter taste, with a very low pH, dark gray color and very sticky texture.

In this case it is necessary to do a wash, in the same way that we do with a very strong lievito. And, after this step, proceed to refresh it in the following way:

- Sourdough 250 g, flour 500 g, water 225 g, egg yolk 20 g and fructose 3 g. And we proceed as usual. Quantities are examples that can and should be adjusted to the quantities with which you feel comfortable at home. Continue with the following refreshments, gradually returning to the quantities of water and flour with which we initially worked, until you obtain a SD with a desired consistency and that grows its initial volume once and a half in a period of 3 or 3 and 1/2 hours. The yolk and sugar/fructose are only used in this first refreshment.

Sourdough is exhausted like the human being.

Last year something happened to me with my stiff SD and, I must admit, it almost gave me something because I thought it was killing it. The fact is that I had a season in which I worked a lot with it, I refreshed it many times because it was growing very fast and, in one of the refreshments something happened to me. My SD barely grew. It floated, but it acquired very little volume.

I searched everywhere for information, I did various tests to refresh it because I did not know what was the cause of that result. Until I spoke to Alain one day. He told me that SD is exhausted like human beings.

If they feed you a lot and demand a lot of effort from you, there comes a time when you get exhausted and can’t do it anymore. The same thing happened to my SD, it became stressed. So what I did was feed it and refrigerate it for 10 days. That way it could “rest” and detox. And so it was. It came back strong!

It is advisable to know well the state in which our SD is and allow a few days of rest so you can recover and continue your activity.

How to correct the acidity of the sourdough.

The fermentation process is directly and strongly influenced by the bacterial activity that can be more or less problematic for the final dough. Depending on the relationship between the two main acids, it will determine a result.

When the presence of lactic acid predominates.

It is often associated with an inappropriate presence of homofermentative lactic acid bacteria. But, they are not necessarily responsible for the excess of lactic a.. It is more difficult to perceive through smell because lactic a., being a non-volatile compound, is odorless. We will only be aware of its presence if we taste the SD. It has a bitter and persistent taste. This taste becomes more noticeable after baking. The following situations may occur:

- This excess of lactic a. leaves us with a weaker primo impasto. In order to solve it, we must make rest in the fridge with the stiff SD so that after a couple of days the production and activity of the yeasts begin again.

- A more sticky impasto, this problem is appreciated, above all, when we do the second impasto. If this happens to us, we must act in the same way as in the previous one. Take a break from the SD for 2-3 days in the fridge. If this problem occurs, we will also notice that a dough with an elasticity and extensibility that will make the dough disperse during kneading in the kneading machine instead of forming a ball making the kneading process very difficult..

- Difficulty in integrating fats into the dough to the point of dividing the gluten mesh. The structure of the dough can be influenced by different factors such as acidity, fat or amount of kneading. It has two poles, positive and negative, which when joined provide consistency and retention capacity to the mesh so that, under pressure of gases, water vapor and fats can avoid the pressure to which it is subjected and avoid problems. Lactic a. has a positive polarity that, when there is an excess of lactic acidity, the positive pole of the latter is imposed on gluten creating an unstable mesh that does not withstand the pressure or fat load. This means that the dough does not agglutinate and becomes impossible to work.

- A product, already baked, crumbles. There are occasions when a product has developed excessive lactic acidity, but not to the point of not allowing the fat to be integrated. Therefore, while working with the dough we could finish kneading and baking the piece. However, placing it upside down would produce a total or partial detachment of the paper capsule. The reason for this problem is that due to a higher lactic acidity, the starch in the flour was prevented from gelling producing an excess of dextrin. A completely non-gelatinized starch does not provide the dough with an optimal structure and, therefore, detachments of the dough occur in the paper capsules.

- Small, round alveolature in the SD. If we carefully examine the SD after finishing the refreshments, we can tell if too much lactic acid has been produced by observing the internal alveolatura of the SD. They will be smaller, due to lower gas production, and round.

All these points allow us to know and understand what is happening to our SD, as well as to remedy it and avoid it so that the problem becomes dominant. We must be able to control it, not it us.

What must we do to achieve balance?

We must act in each and every one of the phases of refreshment and conservation of the SD, directing and inducing actions that produce acetic acid.

Solutions and problems to correct a lactic a. increase.

- Weak impasto with progressive loss of strength: Induce the SDs to produce more heterofermentants and a. acetic. The water with which we cool should be at 75,2º-78,8ºF/24 º-26 º C or 68º-71,6ºF/20 º-22 º C if necessary, low temperatures favor the development of a. acetic.

Night rest at low temperatures, a dry SD at 50ºF/10ºC and a immersed SD in 39,2ºF/4ºC water. - Very sticky impasto: Correct the yeast in the first of the 3 preparatory refreshments, even at this point you can correct the slight excess of a. lactic. In the first refreshment add 20 g of yolk for every 500 g of stiff SD. The yolk acts as a buffer in the yeast absorbing the excess acidity.

- Difficulty integrating fat: In this case we must stop production because there is an excess of lactic a. and we must stabilize and balance the SD. In the first refreshment, in addition to adding the yolk in the proportions previously specified, we will increase the flour in a proportion of 1 to 2. In the second and third refreshment, we will add 0.2% salt, with respect to the amount of flour, to regularize and control acidity. We must also follow the temperature indications to induce the production of a. acetic.

- Detachment of the baked product: The decrease of the % of water also facilitates the decrease of acidity reaching up to 40% with respect to the weight of the flour.

- Small and round alveolate: Make a bagnetto with cold water at 66,2ºF/19ºC before making refreshments. We will use 3 parts of water for each 1 of SD and adding 2 g of fructose (not sugar) per liter of water.

When the presence of acetic acid predominates.

It is much easier to identify since it is a volatile compound, so it can be recognized through smell. It has a pungent and spicy smell, its taste is less bitter than with a surplus of a. lactic, but is noticeable on the tip of the tongue. In this case we can find the following characteristics:

- Resistant and leathery impasto: A very strong and thick gluten mesh develops, being less extensible and leading to tears.

- Product with little taste: Acetic acidity is volatile and is lost during baking, resulting in a product with a noticeable loss of taste. This does not mean that the acidity disappears, negative connotations such as bitter taste and nuances of smell remain in the product.

- Elongated alveolature: The a. Acetic is usually accompanied by a greater vitality of the yeasts, which causes a greater production and expansion of gases along with a larger and elongated alveolatura.

- Greater proliferation of mold: Of the two types of acid, which controls the onset and action of other microorganisms is the a. lactic. So an excess of acetic a. reduces the ability to prevent the appearance of mold in the product.

What must we do to achieve balance?

In this case our objective will be a lactic a. production acting as follows.

Solutions and problems to correct an acetic a. increase.

- Stimulate the conditions that favour the production of lactic a.: in the refreshment phase, dissolve the SD with lukewarm water before integrating the flour. This will result in a higher production of a. lactic acid.

- Increase the % of water to act in the opposite direction mentioned in the previous case, if necessary reaching 55% of water with respect to the final weight of the flour.

- Knead well, paying special attention to the degree of kneading of the SD in the refreshment phase. A well kneaded SD produces acetic a. more easily.

To obtain good or excellent results when making Panettone, in addition to maintaining them over time, it is necessary to maintain a perfect balance in the population of bacteria and yeasts. The industry has this step “easier” because it can control all this, but from the point of view artisanal is more complex. Something that I think gives even more value to the final product because it reflects the love, commitment and care of the product at all times.

In order to have all this under control, it will be enough to follow these steps:

- Impasto temperature: try to be as regular as possible to maintain the balance, 78,8º-82,4ºF/26º-28º C, but much better if we get it to be at 80,6ºF/27º C.

- SD Night maintenance temperature: The ideal will be 60,8º-64,4ºF/16º-18ºC, both for the SD with dry method and submerged in water. In the latter case, the SD should be harder and dryer since during rest it will absorb water and tend to disintegrate.

- Night rest time: Allows the SD to be purified of nonspecific harmful microorganisms through the excess acidity produced. The ideal is 16-18 hours.

- Percentage of hydration and consistency of impasto: A very hard dough favours excessive development of a. acetic, so add 4% water (44-46% depending on the flour) and knead very well. Laminating and folding the SDh, as we do when we refresh it, helps to oxygenate it and allows a better reproduction of the yeasts.

BRIEF SUMMARY:

Lactic acid -> Weakest impasto, sticky, difficult to incorporate fat, product that comes off the paper capsule, alveolatura round and small.

Acetic acid -> Impasto more resistant and leathery, final product with little flavour, elongated alveolatura and greater proliferation of mold in the product.

The techniques to preserve and use the SD are many and varied. All of them are adapted to the different needs of those who use it, as well as different modes of production, taste, execution… But the most important thing of all is to regularize the degree and consistency of the impasto, the temperature of the impasto and the time and temperature of conservation. Only in this way will we be able to maintain a constant maturity and qualities.

Ingredients

FIRST REFRESHMENT:

8:00 am, temperature 78,8º-82,4ºF/26º-28º C

- 30 g stiff sourdough

- 30 g Manitoba flour,W=360-380

- 10,6-12,6 g water (take a look, because it will absorb more water during the bagnetto), (78,8º-82,4ºF/26º-28º C)

SECOND REFRESHMENT:

11:45 pm, temperature 78,8º-82,4ºF/26º-28º C

- 60 g stiff SD (from the first refreshment)

- 60 g Manitoba flour, W=360-380

- 25,2 g water, (78,8º-82,4ºF/26º-28º C)

THIRD REFRESHMENT:

15:45 pm, temperature 78,8º-82,4ºF/26º-28º C

- 140 g stiff SD (from the second refreshment)

- 140 g Manitoba flour, W=360-380

- 59 g water, (78,8º-82,4ºF/26º-28º C)

Instructions

Prepare the SD for the 3 preparatory refreshments.

- In case of working with a dry/sac stiff SD we must take into account that our impasto will be acidic, so we will need to make a bagnetto with cold water at about 68ºF/20º C to reduce acidity. In this case, it should be cut into slices and placed in a bath of water sweetened with 0.5 g of sugar/litre of water for 15/18 minutes following the instructions specified above. Then we proceed as detailed in the elaboration.

- In case of working with a stiff SD immersed in water, we will do it as detailed below.

Bagnetto.

- Start at 7:40 am.

- Turn the container and with the hand placed under this one, we gather the SD that will fall little by little. This step can be done in the kitchen sink or on a large bowl, as you prefer.

- Remove the slug with the hand and drain between the two hands gently to remove the excess water. We will do it as if we were squeezing a sponge.

- Place on a plate.

- Fill a bowl with warm water at 91,4º-95ºF/33º-35ºC with the proportion specified above. Ratio of quantity of water : SD, 3:1.

- Dissolve 0.5 g of sugar per litre of water. If it is less, we calculate the proportion.

- Add the SD and let it rest for 15-18 minutes. Normally, what should happen is that the SDs, as soon as it is introduced, sinks. And as the minutes pass, it will float.

- After this time we drain the SD and proceed to make the first preparatory refreshment.

First refreshment.

- Start at 8:00 am.

- Mix the SD with the flour and water (approximately 42% with respect to the weight of the flour). The final temperature of the dough should be 78,8ºF/26ºC.

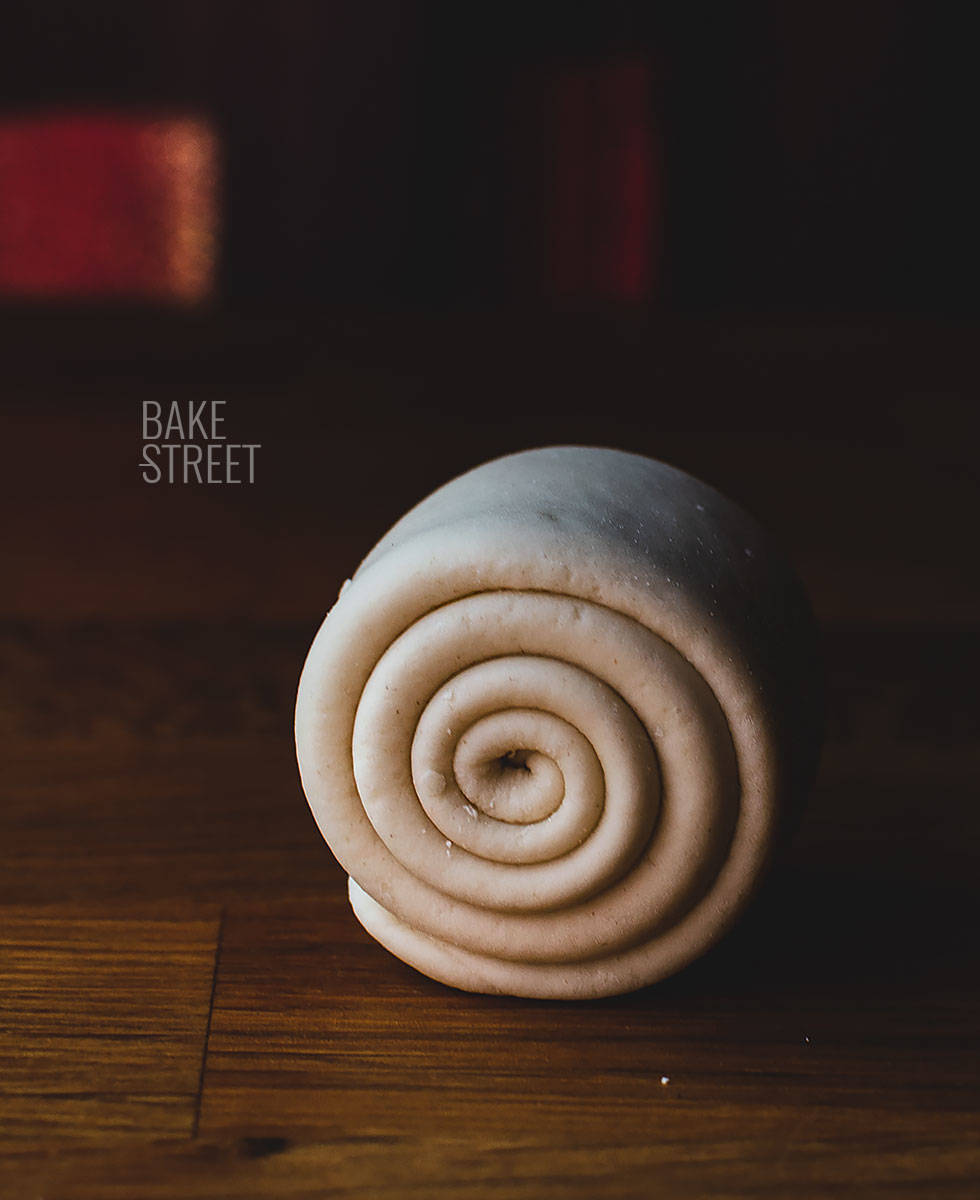

- Knead until you get a soft dough, smooth and silky to the touch. Its consistency should be firm, not sticky adhering to the hands or work surface. If this happens, it will be because we have exceeded in the hydration of the SD.

- Shape in the same way that we proceed to work with it when we made the stiff SD. You can watch it in this video in which I show you how to knead, stretch and shape the SD. And in this post I detail the whole process.

- Place into the container and cover with water at 78,8º-82,4ºF/26º-28º C to cover the top of the SD.

- Leave for about 3-4 hours, if possible, in a controlled environment with a temperature of 78,8º-82,4ºF/26º-28º C. In my case I place it inside the oven with a homemade fermenter that my husband has made me.

- The SD will float and grow in volume.

Second refreshment.

- Start at 11:45 am.

- Drain the SD and proceed to perform the same process as in the first refreshment, but with the amounts that I specify for this step.

- Leave in a controlled environment with 78,8º-82,4ºF/26º-28º C for 3-4 hours.

Third refreshment.

- Start at 15:30 pm.

- Drain the SD and proceed to perform the same process as in the first refreshment, but with the amounts that I specify for this step.

- Leave in a controlled environment with 78,8º-82,4ºF/26º-28º Cfor 3-4 hours.

- After this time, (between 18:30 or 19:15 pm) we will have our SD ready to proceed to elaborate Primo Impasto of our Panettone.

Notes

- Can another variety of flour be used? Never with a strength less than W=360. That is to say, we cannot use a flour of force because the process is not going to go well.

- What happens if I use flour with a strength greater than W=400? We will have problems during the fermentation process. A flour with a large amount of strength has less enzymatic activity so it will give us problems during the fermentation process. Especially when we start the process to create a stiff SD.

- The container we use should not be too big because otherwise the SD will expand too much and disintegrate. We need a container that contains it and grabs it. This step is very important.

- Since in each refreshment we will increase the amount of each element, we will need a different container in each step. In my case I use a small glass in the first, a slightly larger and wider glass in the second and an elongated Ikea plastic container in the third.

I think two things can happen today... That you hate me for the quantity of theory and text that I have left you, or that you love me due to this sermon that, without a doubt, will be of great utility to you to know How to make the 3 preparatory refreshments for the stiff sourdough. Of course, to make wonderful Panettones!

I am aware that this whole process requires a lot of dedication, time and love. But it is the price to be able to enjoy a product like the Panettone and with wonderful and spectacular conditions.

I thought I was going to write 3 posts to make panettone: How to make a stiff SD, how to make the 3 preparatory refreshments and the recipe to make the Panettone. But reading and studying well all the theory that surrounds this product, I still get another post before I leave you the recipe of the Panettone.

Of course, I owe all this knowledge to one of my treasures, PH 4.1. Scienza e artigianalità della pasta lievitata. For me it is a book that I must recommend, it is exceptional. The bad thing about it is that it is written in Italian and, at least in my case, it takes me a great job to translate it and then read it again to learn, know, apply and, finally, make it reach you in the easiest way possible. If you can, buy it because it will be a jewel on your shelf.

I wish you a wonderful start to the week!

Big hugs,

Eva

Sources: PH 4.1. Scienza e artigianalità della pasta lievitata

This post contains affiliated links